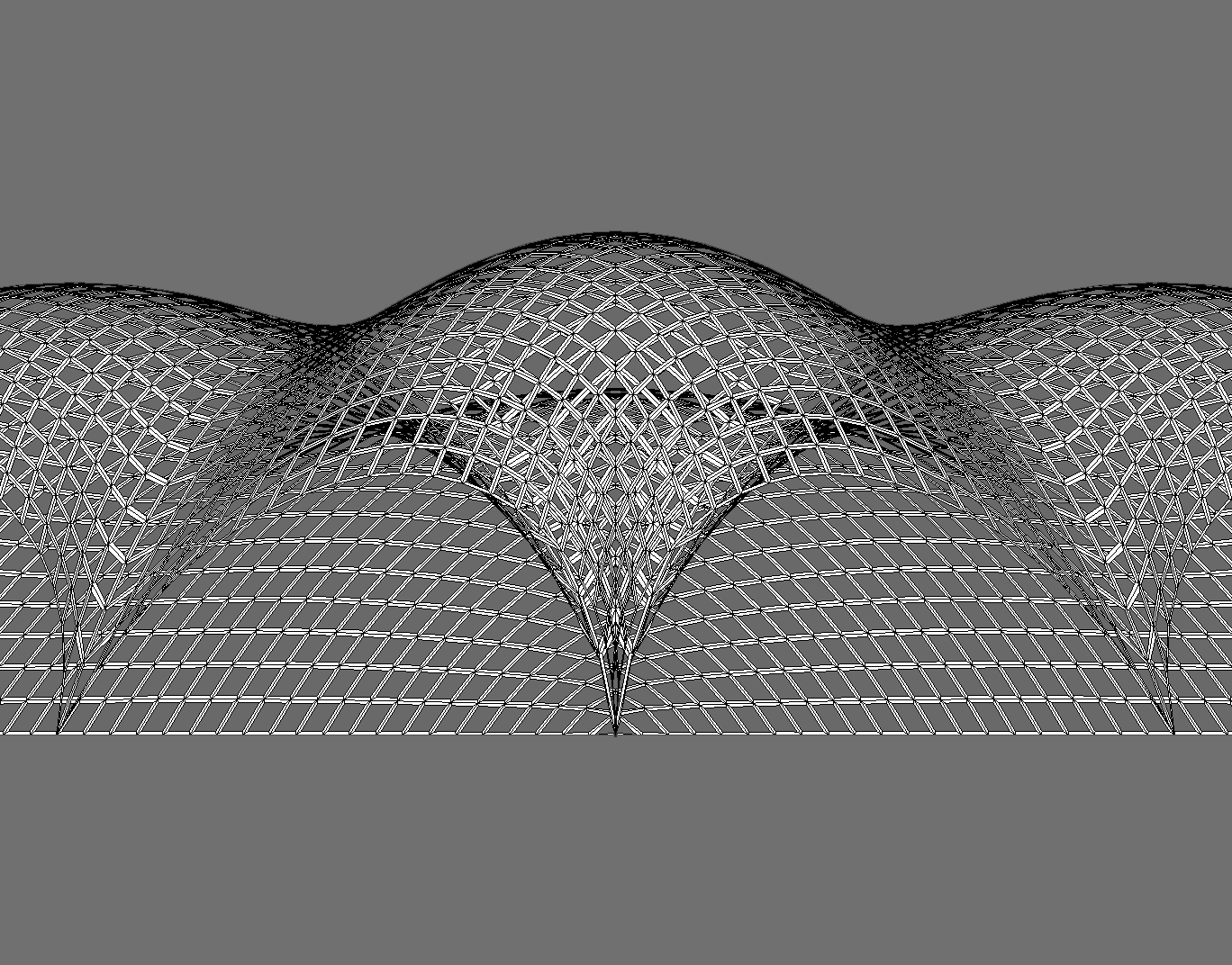

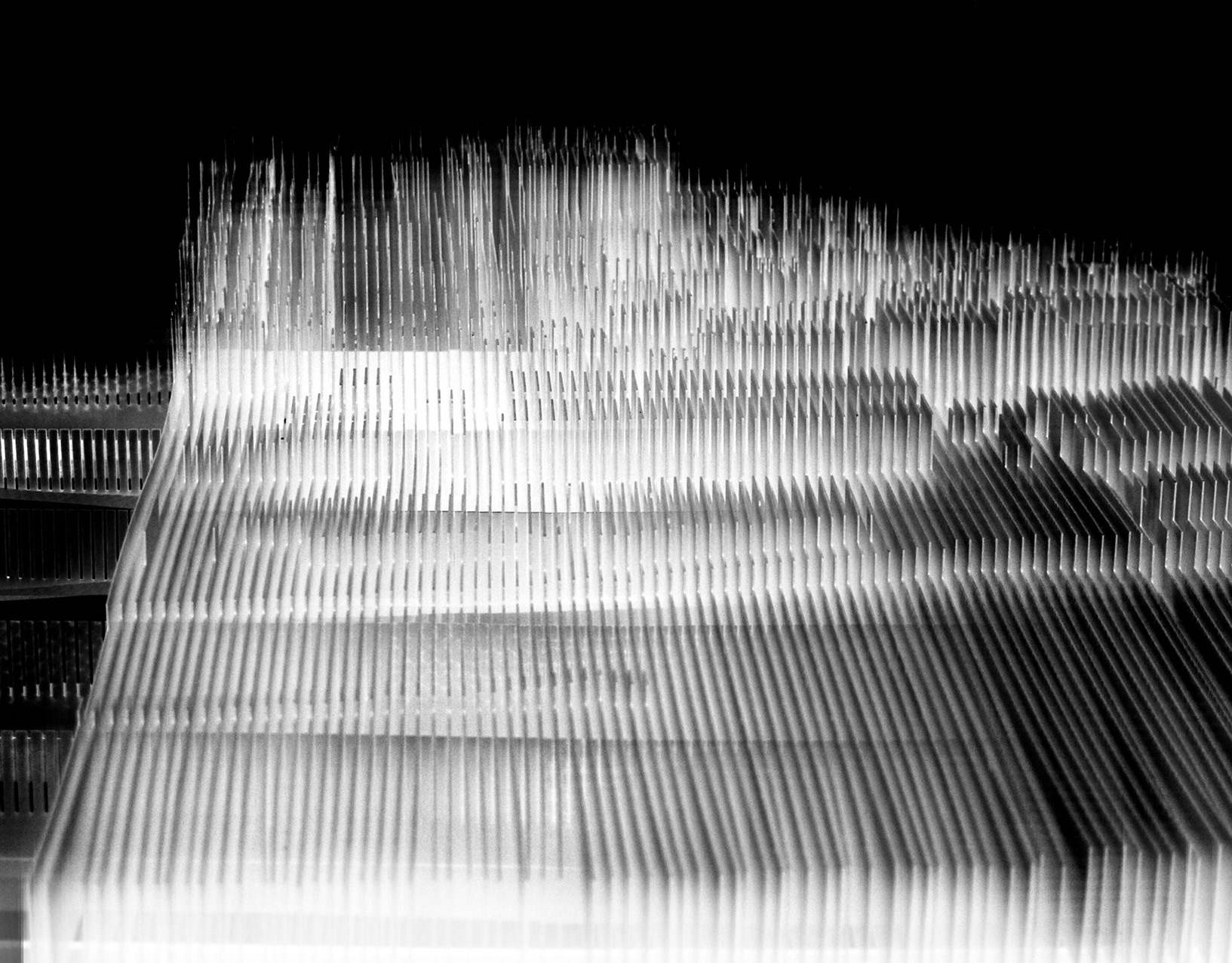

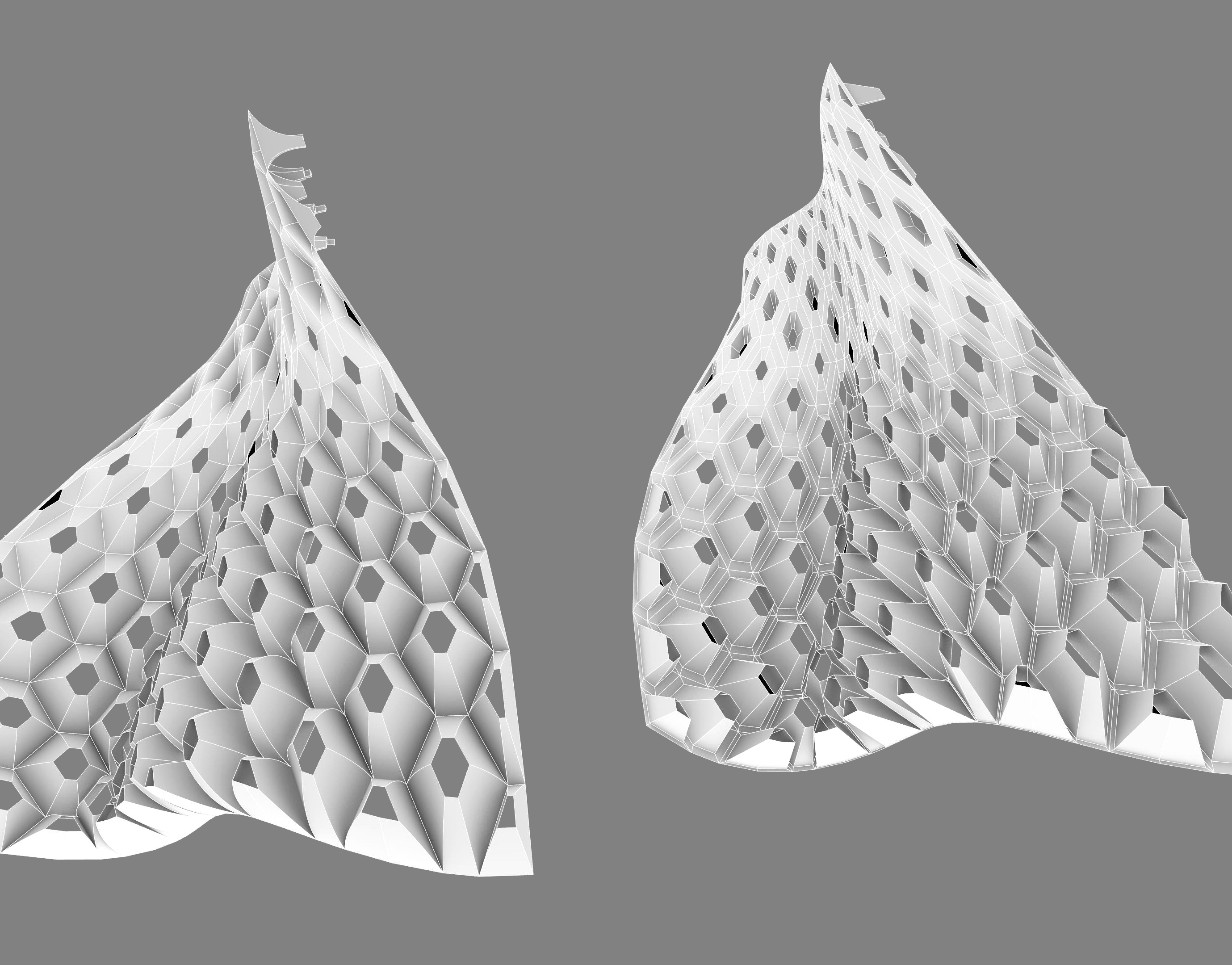

Triangulated integrities project first started with trapezoid based geometries with specific heights. Basically the light is let through the lines in between the trapezoids in the first trial. Second stage was to try with differing heights in these connection lines and experimenting with various heights of the trapezoids and triangulates themselves. We have 4 different facades with one equilateral trapezoid and three triangulates. Two sides of triangulates differ also in the base areas to let more light with smaller sized triangles as more thinner connections exist. The more connections occur in between units, the more light comes out. So in each facade, we play with heights and sizes of basesto have variable light effects

Second experiment is based on playing with different thicknesses in the base part and also with the triangulates. 4 different facades achieved with different properties in cutting which forms different lights.4 transversal sections that differ in base thickness,triangulate thickness and basic geometry form different layers of light.Two facades with triangulates differ also in the base areas to let more light with smaller sized bases as results in more connections. The more connections occur in between units, the more light comes out. So in each facade, different thickness and various sizes for bases and geometries are achieved.

The Milling Process

Detailed photography of the 4 Facades

Triangulated Integrities is a Digital Fabrication learning project.